Computer-Aided Design (CAD) and Engineering Technologies

Program Description

Redefine what is possible through CAD and Engineering Technologies!

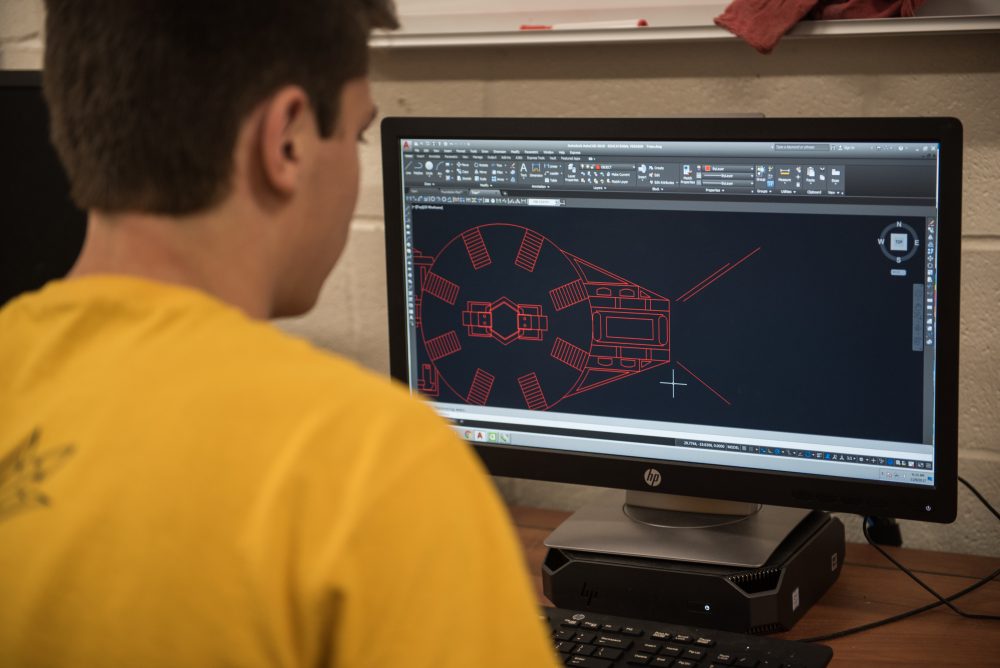

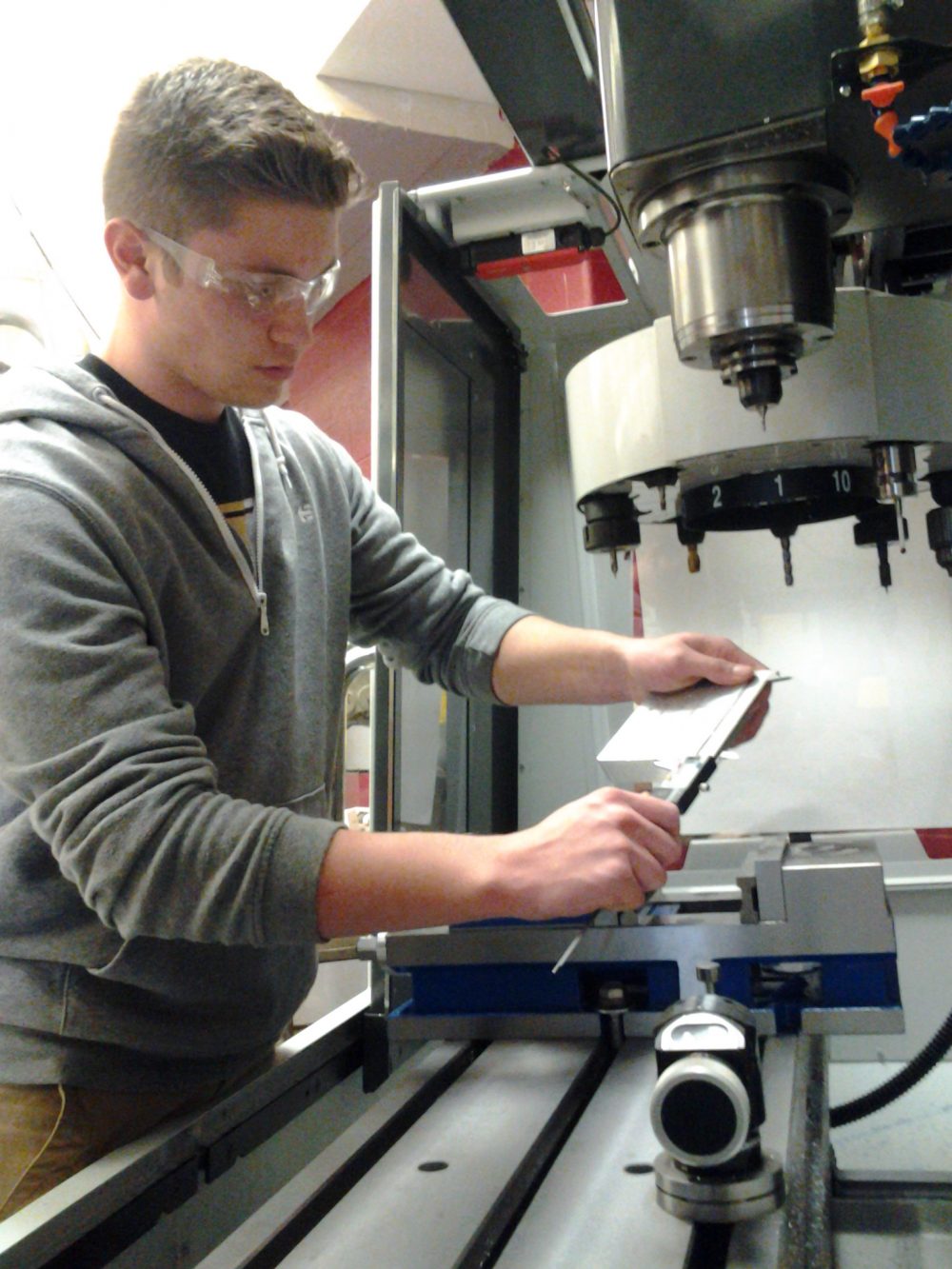

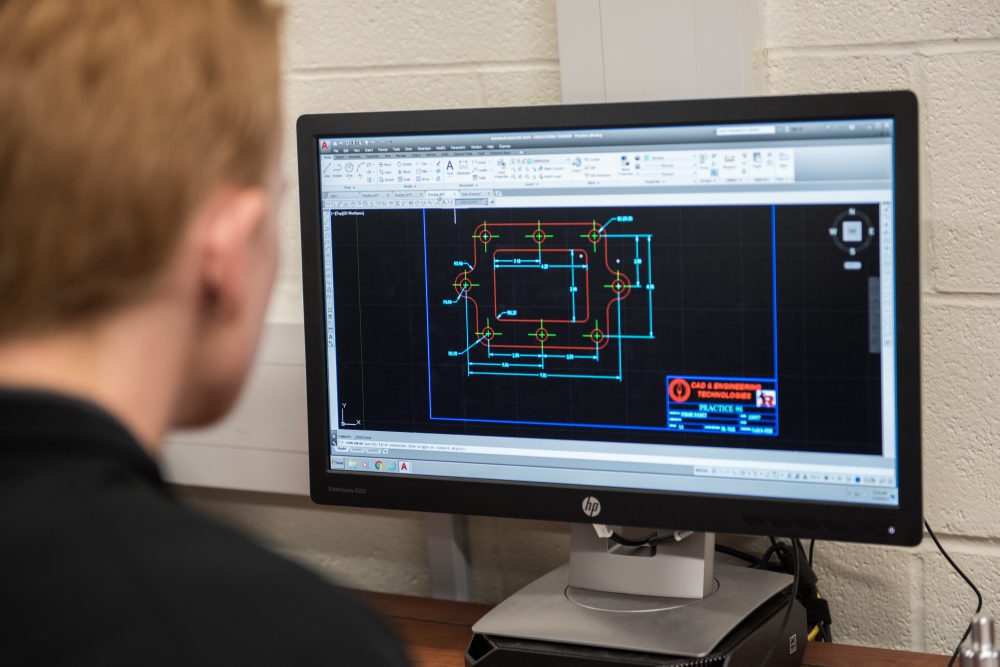

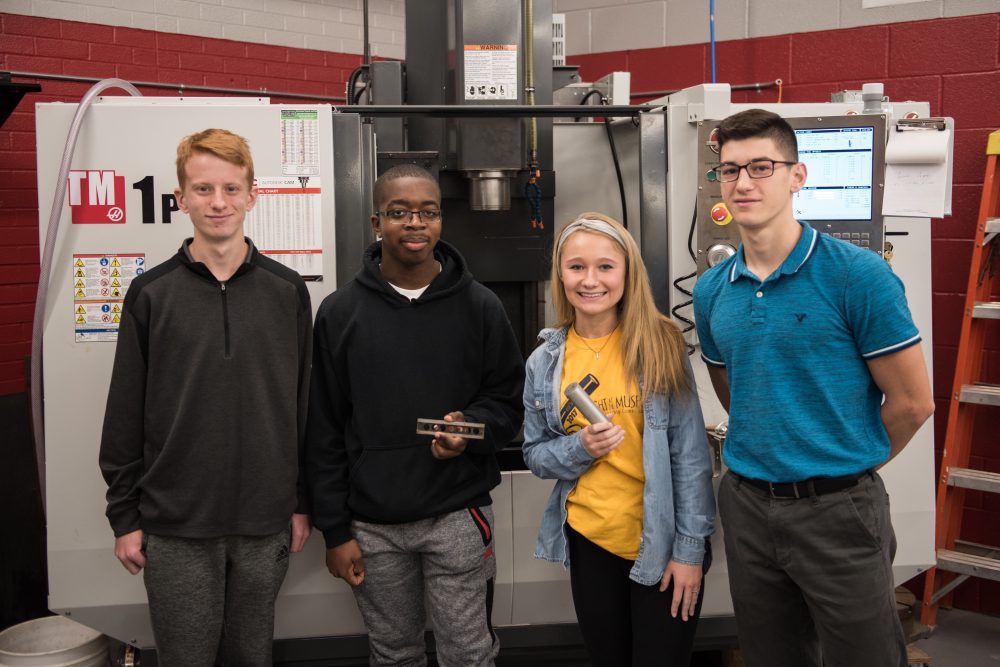

Students will use the latest industry-standard software and equipment to produce working drawings, 3D solid model designs, parts, and assemblies. Students will also have the opportunity to program and operate CNC machines (router, lathe, mill, and water jet) to produce manufactured products using metal, wood, and plastic. Students will also operate 3D printers and laser engravers in fabricating various engineered and designed products. Advanced Manufacturing and Welding processes in industry will be explored.

This exciting, professional College Tech Prep offering is designed to prepare students for careers in the Engineering and Advanced Manufacturing career fields. Students will network with industry experts and partners, working in high-demand Advanced Manufacturing.

Senior-level internships/industry placement opportunities are available to qualified students.

Advanced technologies, coupled with the need to update and improve manufacturing facilities and product design, should fuel the demand for professionals in Advanced Manufacturing, and engineering technologies. According to the latest data, 7,400 jobs within a 100-mile radius of Akron, Ohio currently exist.

Upon successful completion of the program, students will be eligible to earn up to 6 college credits (CTAG) to any Ohio public university for Computer-Aided Drafting and Design and Manufacturing Processes in an Engineering Technology program.

Take a 3D virtual tour of our 3D Prototyping Lab and our Advanced Manufacturing Center!

Digital Program Notebook

Program Requirements

GRADE LEVEL: 10, 11, 12

SCHOOL: Kent

PROGRAM LENGTH: Two Years

CREDIT AT KENT:

Level I: CP or Comp English (1cr); CADET IA (1cr); CADET IB (1cr).

Level II: CADET IIA (1.5cr); CADET IIB (1.5cr). CADET II Capstone (1cr).

Virtual Tour

Program Overview

Skills Necessary for Success

Detail-oriented problem solver

Ability to visualize projects

Affinity for mathematics

Ability to work independently and as a team member

Positive attitude, critical thinker

Interest in designing and building

Use and implement precise measurements and calculations

Professional Pathway

Engineering technician

Machine Technician

Manufacturing Engineer

Architect

CNC programmer/operator

Landscape architect

CAD Designer

Interior designer

Furniture Engineering Draftsman

Machinist

Higher Educational Opportunities

College credits available. See page 32.

Bachelor’s degree

Associate’s degree

Internships

Helpful Background

Career interests/helpful background

Computer technology

Manufacturing process

Blueprint design or production

Keyboarding skills

Recommendations

Excellent attendance record

Geometry

Minimum 2.5 GPA

Utilize computer technologies

Meet the Instructors

Stories & Projects from Computer-Aided Design (CAD) and Engineering Technologies

Capstone

April 03, 2018

During Spring Break,instructors Troy Spear and Jeff Bee and , two seniors from CAD & Eng Tech Level II, Richie Morroco and AJ Tassone were the first educators, students and educational institution in the United States to get trained on a Mill Turn module for MasterCAM which is a new industrial duty software that the CAD & Engineering Technologies program is utilizing to integrate student designs with machines to bring designs to life. This module is specifically designed to be used with our new Turning Center. Both Richie and AJ benefitted from the instruction that they will be utilizing for their capstone projects that each is working on. AJ's capstone project is a 5" Bass fishing lure mold. He intends to make three different sizes 5", 4", 3" of the same design. Using Mastercam to input his Solidworks file he was able to create the tool paths for his mold very quickly. Tooling was supplied by Kyocera SGS Precision tools. Kevin Richardson of Fastech Inc., Mastercam reseller and trainer, was able to instruct Richie and AJ both in the techniques used in creating toolpaths from solid models.

Computer Aided Design (CAD) & Engineering Technologies Students Tour Kennametal in Solon

November 17, 2017

Computer Aided Design (CAD) & Engineering Technologies students toured Kennametal in Solon, Ohio. They were able to see and hear from Kennametal employees how the carbide insert tooling they create is used to make everything from jet engines to helicopter rotors. Kennametal offers internships and paid tuition for apprenticeships and other training as well. Computer Aided Design & Engineering Technologies students learn about and use carbide insert tooling in both manual and CNC machines.

Computer Aided Design (CAD) & Engineering Technologies Visit Delta Systems

November 17, 2017

Computer-Aided Design (CAD) & Engineering Technologies students visited Delta Systems in Streetsboro and witnessed local advanced manufacturing. They toured circuit board soldering and assembly division and saw how Delta Systems employees make and assemble safety components and switches for outdoor power equipment. Delta Systems employs many different positions from steel stamping, tool and die, machining and assembly to get the job done.

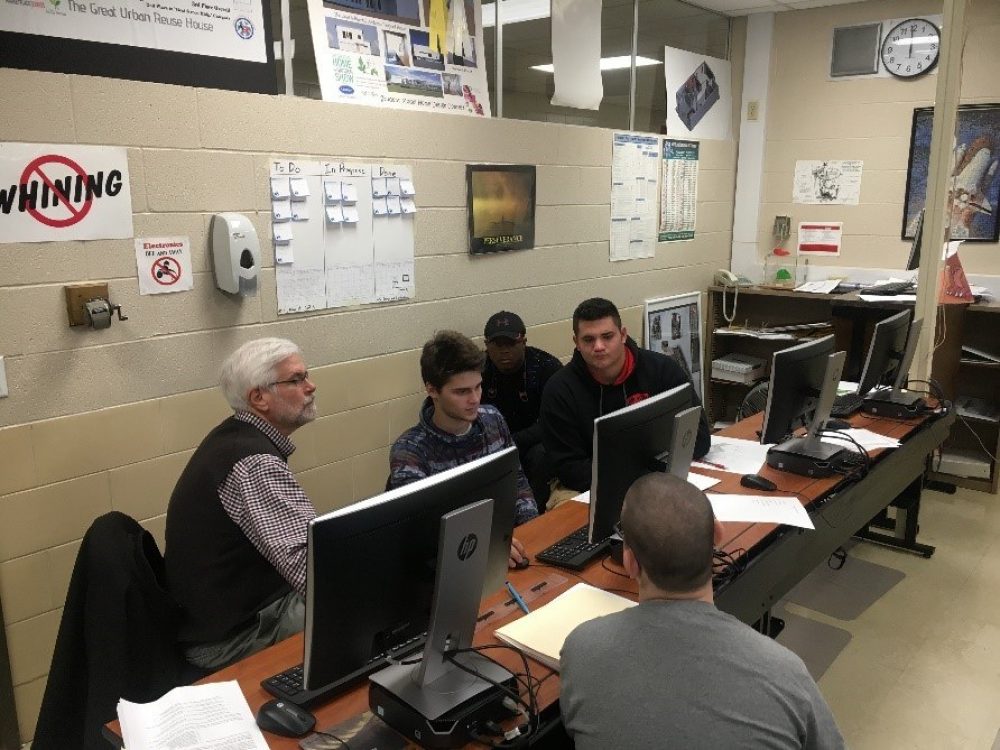

DS Architecture works with Computer-Aided Design (CAD) & Engineering Technologies ll students

November 16, 2017

Two architects from DS Architecture worked with students from the Computer-Aided Design (CAD) & Engineering Technologies ll program on their residential house designs. The students are participating in this year’s Student Model Home Design Contest.

Doug Fuller and Paul Romanic volunteered their time and expertise to review and discuss the Computer-Aided Design (CAD) & Engineering Technologies students’ designs. The students learned about how an architect approaches a project when considering the client’s needs and specifications.